Overview

The Nissan NP200 1.6 is powered by a 1.6-liter inline four-cylinder engine with the K7M engine code. This engine features a single overhead camshaft and eight valves, delivering approximately 64 kW (around 86 horsepower) at 5,500 rpm and a torque of 128 Nm at 3,000 rpm. The K7M engine is designed for reliability and simplicity, making it suitable for light commercial use, everyday driving, and work-oriented applications. Its robust yet straightforward architecture contributes to the long-lasting reputation of the NP200 bakkie. Overall, the K7M engine’s combination of durability, efficiency, and ease of maintenance ensures that the NP200 remains a dependable choice for both personal and commercial use.

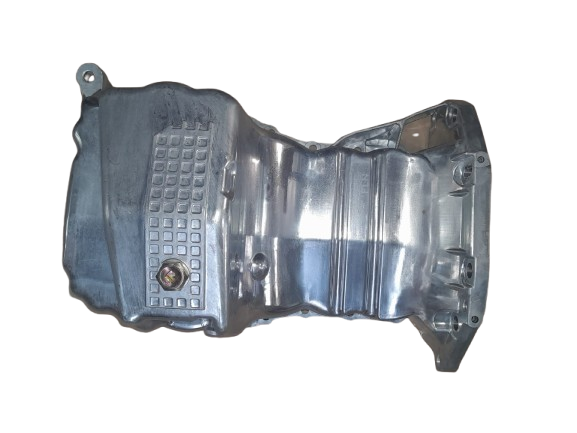

What is the Oil Sump?

The oil sump, also known as the crankcase sump, is the component attached to the bottom of the engine block that serves as the reservoir for engine oil. In the NP200 1.6 K7M, the engine employs a wet-sump system, meaning the oil is stored in the sump itself and circulated throughout the engine by the oil pump. The sump’s primary function is to supply oil to all moving parts of the engine, such as the pistons, crankshaft, camshaft, and bearings, ensuring proper lubrication and reducing friction. Additionally, the sump assists in cooling the engine by allowing the oil to dissipate heat generated during combustion and friction, thereby maintaining optimal operating temperatures. Without a properly functioning sump, the engine risks inadequate lubrication, overheating, and serious mechanical damage.

Construction and Design Features

The NP200 1.6 K7M sump is typically constructed from durable materials such as cast steel or cast aluminum to withstand mechanical stress and resist corrosion. Its pan-like design is sealed against the engine block using a gasket to prevent oil leaks. Internally, the sump contains an oil pump pickup tube, which draws oil from the lowest point of the sump and delivers it to the oil pump. It also features baffles that prevent excessive oil movement when the vehicle is in motion, ensuring a consistent oil supply to the engine even during cornering or driving over uneven terrain. Some variants may include oil level monitoring provisions to detect low oil levels and protect the engine from damage.

Maintenance and Common Issues

Maintaining the sump is essential for engine longevity. Over time, the sump gasket or seals can degrade, leading to oil leaks that may reduce oil levels and impair lubrication. Sludge or debris accumulation inside the sump can obstruct the pickup tube, causing oil starvation. Regular oil changes with the correct viscosity, along with inspections for leaks and cleanliness, are crucial to prevent these problems. Neglecting the sump can result in accelerated wear of engine components and more costly repairs.

Suitability for NP200 Use

The design of the K7M sump aligns well with the NP200’s role as a reliable and economical work bakkie. Its sturdy construction, internal baffles, and efficient oil circulation system provide stable lubrication even under load or on uneven roads. By ensuring proper lubrication and cooling, the sump contributes to engine durability, efficiency, and reduced maintenance requirements, making it ideal for both daily driving and commercial use.

Summary

The oil sump of the Nissan NP200 1.6 K7M engine is a fundamental component that supports engine lubrication, cooling, and overall reliability. Its robust construction, thoughtful internal design, and proper maintenance are essential for protecting the engine and ensuring long-term performance. For work-oriented vehicles like the NP200, the sump plays a critical role in maintaining engine health under demanding conditions.